![]() Phone Number

Phone Number ![]() Cilent Portal

Cilent Portal

866-748-2551

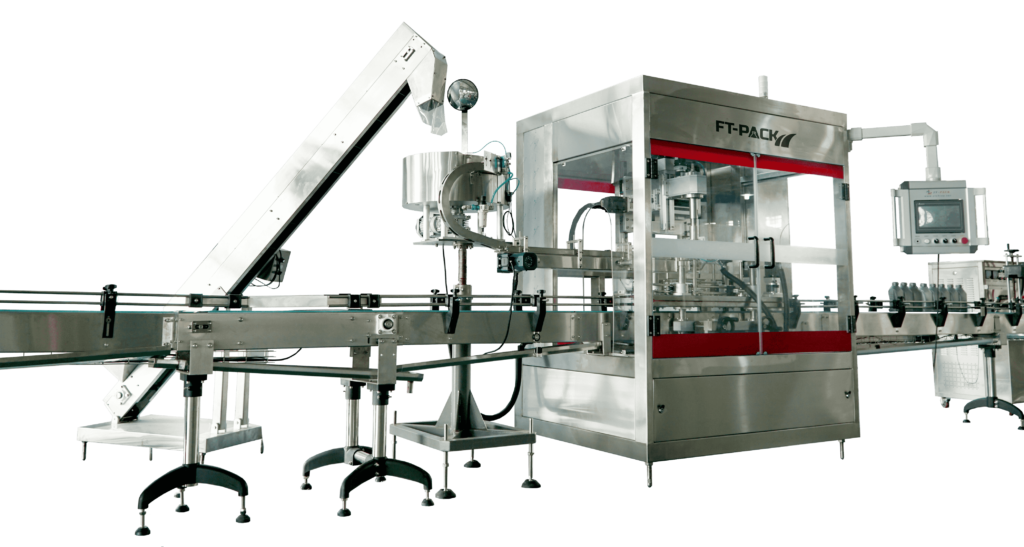

Capping Machines

"Versatile Solutions for Every Need"

Capping Machines

FT-PACK’s capping machines are designed to meet the diverse needs of various industries, offering reliable and efficient solutions for sealing containers of all shapes and sizes. Our state-of-the-art capping technology ensures your products are securely sealed, maintaining product integrity and extending shelf life.

Key Features

Our capping machines offer unmatched versatility, handling a wide range of container types and cap styles across multiple industries such as food and beverage, pharmaceuticals, cosmetics, chemical products, and automotive. They provide precision and efficiency with advanced torque control and high-speed operation, ensuring consistent and accurate capping. Customizable options and modular designs allow for easy integration and tailored solutions, including diptube assembly and insertion. User-friendly interfaces minimize downtime with quick changeovers, while durable construction ensures long-lasting performance and reduced maintenance costs.

Types of Capping Machines

1.Spindle Cappers

Description: Ideal for high-speed applications, spindle cappers use a series of spinning wheels to tighten caps onto containers.

Features: Continuous motion operation, adjustable torque settings, and easy setup for various cap sizes.

2.Pick and Place Cappers

Description: Perfect for precise cap placement, these cappers use a robotic arm to pick up and place caps onto containers.

Features: Accurate cap positioning, gentle handling of delicate caps, and adaptable to various cap types.

3.Tracking Cappers:

Description: Designed for inline capping on moving conveyors, tracking cappers ensure caps are applied accurately without stopping the line.

Features: Real-time tracking of containers, consistent torque application, and seamless integration into production lines.

4.Custom Solutions

Description: Tailored to specific industry needs, our custom capping solutions include diptube assembly and insertion.

Features: Customized design for unique applications, specialized handling, and integration with other packaging equipment.

Applications:

• Food and Beverage

• Pharmaceuticals

• Cosmetics

• Chemical Products

• Automotive

Why Choose FT-PACK Capping Machines

Expertise: Decades of experience in providing packaging solutions.

Support: Comprehensive customer support and after-sales service.

Quality: Commitment to delivering high-quality, reliable equipment.

Contact Us: To learn more about our capping machines or to request a quote, please contact our sales team at [contact information] or fill out our online inquiry form.